Isingeniso:

Imishini yokushisela indawo yebhethrizingamathuluzi abalulekile ekukhiqizeni nasekuhlanganiseni amaphakethe ebhethri, ikakhulukazi emikhakheni yezimoto zikagesi kanye nezamandla avuselelekayo. Ukuqonda isimiso sabo sokusebenza nokusetshenziswa okufanele kungathuthukisa kakhulu ukusebenza kahle kanye nekhwalithi yokuhlanganisa ibhethri.

Isimiso Esisebenzayo Somshini Wokushisela I-Battery Spot

Ukushisela indawo yebhethri kuyinqubo ehlanganisa izindawo ezimbili noma ngaphezulu zensimbi ndawonye ngokusebenzisa ukushisa nokucindezela. Lokhu kufezwa ngokusebenzisa amandla kagesi ageleza phakathi kwezinto zokusebenza. Izingxenye eziyisisekelo ze-aumshini wokushisela indawozihlanganisa:

1. Ama-Electrodes: Lawa ngokuvamile enziwa ngethusi futhi asetshenziselwa ukuqhuba ugesi ezintweni ezishiselwe. Idizayini yama-electrode ingahluka kuye ngohlelo oluthile kanye nohlobo lwezinsimbi ezihlanganiswayo.

2. I-Transformer: I-transformer inciphisa i-voltage ephezulu ukusuka emthonjeni wamandla kuya ku-voltage ephansi efanelekile inqubo yokushisela ngenkathi ikhulisa yamanje.

3. Uhlelo Lokulawula: Imishini yesimanje yokushisela amabala ifakwe izilawuli ezincane ezivumela ukulawula okunembile phezu kwemingcele yokushisela, njengamanje, isikhathi, nokucindezela.

Inqubo iqala lapho ama-electrode ebekwe ezindaweni ezizoshiselwa. Umsinga ube usudluliswa kuma-electrode, akhiqize ukushisa ngenxa yokumelana nogesi endaweni okuhlangana kuyo izinsimbi. Lokhu kushisa kuphakamisa izinga lokushisa lifinyelele endaweni yokuncibilika kwezinto, kubangele ukuthi zihlangane ndawonye. Ingcindezi esetshenziswa ama-electrode isiza ukuqinisekisa isibopho esiqinile ngokunciphisa ukwakheka kwama-oxide ekuhlanganyeleni.

Ngemva kwesikhathi esifushane sokupholisa, ijoyinti elishiselwe liyaqina, okuholela ekuxhumekeni okuqinile kwemishini. Yonke le nqubo ivamise ukushesha kakhulu, ithatha ingxenye encane nje yomzuzwana.

Izindlela Zokusebenzisa Umshini Wokushisela Ibhethri Spot

- Ukulungiselela

Ngaphambi kokusebenzisa aumshini wokushisela indawo yebhethri, kubalulekile ukulungisa indawo yokusebenza nezinto zokwakha:

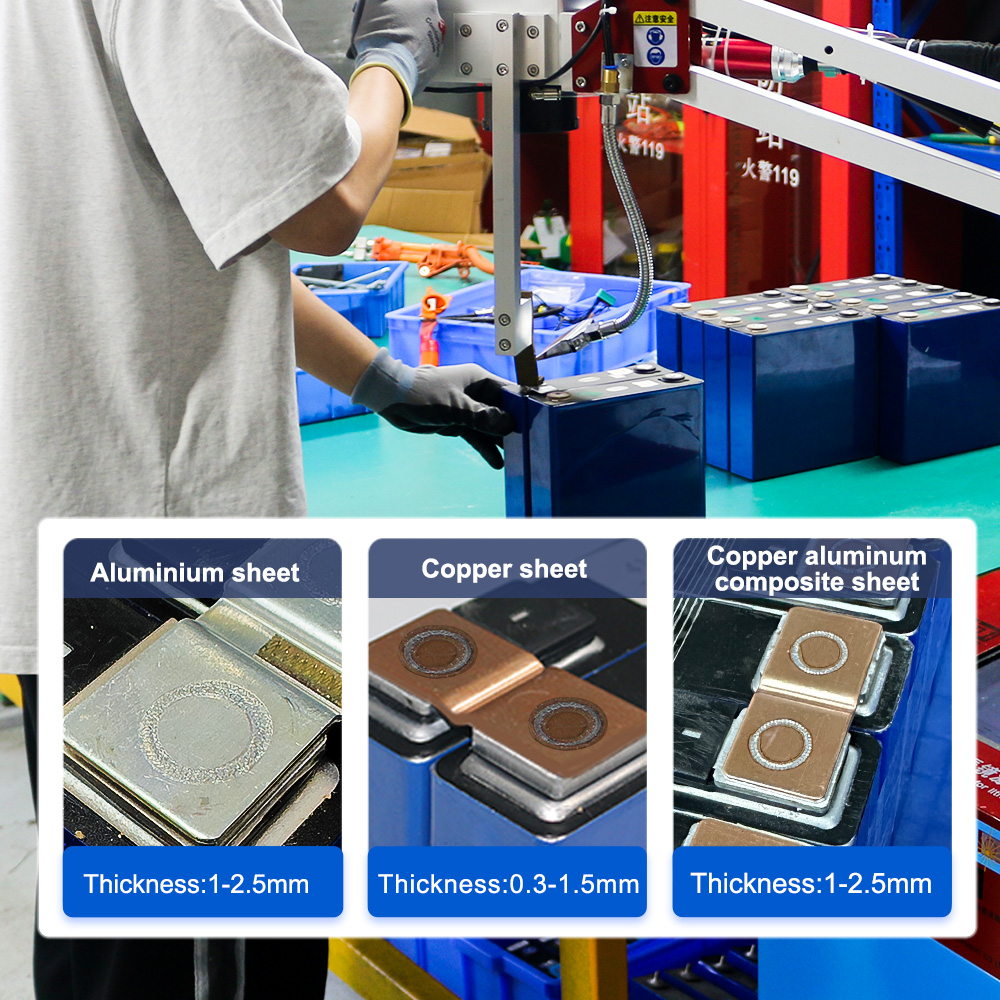

1. Ukukhethwa Kwempahla: Qinisekisa ukuthi izinsimbi ezishiselwayo ziyahambisana. Izinto ezijwayelekile zokuxhunywa kwebhethri zifaka insimbi ye-nickel-plated ne-aluminium.

2. Ukuhlanza Ubuso: Hlanza izindawo ezizoshiselwa ukuze ususe noma yikuphi ukungcola, okufana namafutha, ukungcola, noma i-oxidation. Lokhu kungenziwa ngokusebenzisa ama-solvents noma izinto eziqhumayo.

3. Ukusethwa Kwezisetshenziswa: Misa kahle umshini ngokwemiyalelo yomkhiqizi. Lokhu kuhlanganisa ukulungisa ama-electrode nokuqinisekisa ukuthi zonke izici zokuphepha ziyasebenza.

- Spot Welding MachineInqubo yokushisela

1. Ukuma: Beka amaseli ebhethri nemigqa yokuxhuma endaweni efanele phakathi kwama-electrode. Qinisekisa ukuthi ziqondile ukugwema noma yikuphi ukungahambi kahle ngesikhathi senqubo yokushisela.

2. Ukusetha Amapharamitha: Lungisa imingcele yokushisela ohlelweni lokulawula, okuhlanganisa ukuqina kwamanje, isikhathi sokushisela, nokucindezela. Lezi zilungiselelo zingase zihluke ngokusekelwe ezintweni kanye nogqinsi olushiselwe.

3. Ukushisela: Vuselela umshini ukuze uqale inqubo yokushisela. Gada ukusebenza ukuze uqinisekise ukuthi ama-electrode agcina ukuthintana okufanele kanye nokuthi wamanje uhamba ngendlela efanele.

4. Ukuhlola: Ngemva kokushisela, bheka ngokubonakalayo amalunga noma yikuphi ukukhubazeka, njengokuhlanganisa okungaphelele noma i-spatter eyeqile. Ezinye izinhlelo zokusebenza zingadinga ukuhlolwa okwengeziwe kokuqhubeka kukagesi noma amandla emishini.

Ukucatshangelwa Kokuphepha

Ukusebenza ngeimishini yokushisela amabalakungadala izingozi ezithile. Hlala ulandela izimiso zokuphepha:

1. Igiya Lokuvikela: Gqoka okokusebenza okufanele kokuzivikela (i-PPE), okuhlanganisa amagilavu, izibuko zokuphepha, namaphinifa ukuze uvikele ezinhlansini nasekushiseni.

2. Ukungenisa umoya: Qinisekisa ukuthi indawo yokusebenza inomoya omuhle ukuze ugweme ukuhogela noma iyiphi intuthu ekhiqizwa ngesikhathi sokushisela.

3. Izinqubo Zesimo Esiphuthumayo: Zijwayeze nezinqubo zokuvala shaqa izimo eziphuthumayo futhi uqinisekise ukuthi umshini unezitobhi ezifinyelelekayo eziphuthumayo.

Isiphetho

Imishini yokushisela indawo yebhethriidlala indima ebalulekile ekuhlanganiseni kahle kwamaphakethe ebhethri. Ukuqonda isimiso sabo sokusebenza nokulandela izindlela zokusetshenziswa ezifanele kungaholela ekushiseleni kwekhwalithi ephezulu kanye nokukhiqiza okuthuthukisiwe. Ngokubeka phambili ukuphepha nokulungiselela, opharetha bangasebenzisa le mishini ngempumelelo ezinhlelweni ezihlukahlukene, okunomthelela ekuthuthukisweni kobuchwepheshe bokugcina amandla.

Uma unombono wokuhlanganisa ibhethri ngokwakho, uma ufuna indawo yokushisela enembayo ephezulu yokushisela ibhethri lakho, khona-ke isishisela esisuka kwa-Heltec Energy sikufanele ukucatshangelwa.

Uma unemibuzo noma ungathanda ukufunda okwengeziwe, sicela ungangabazifinyelela kithi.

Isicelo sekhotheshini:

U-Jacqueline:jacqueline@heltec-energy.com/ +86 185 8375 6538

Sucre:sucre@heltec-bms.com/ +86 136 8844 2313

U-Nancy:nancy@heltec-energy.com/ +86 184 8223 7713

Isikhathi sokuthumela: Sep-20-2024