Isingeniso:

Ibhethri ye-lithiumibhethri elishajekayo eline-lithium njengengxenye eyinhloko. Isetshenziswa kabanzi kumadivaysi e-elekthronikhi ahlukahlukene kanye nezimoto zikagesi ngenxa yobuningi bayo bamandla, isisindo esilula kanye nempilo yomjikelezo omude. Mayelana nokucutshungulwa kwamabhethri e-lithium, ake sibheke izinqubo zokushisela indawo, ukubhaka okuyisisekelo kanye nomjovo we-lithium wamabhethri e-lithium.

Spot welding

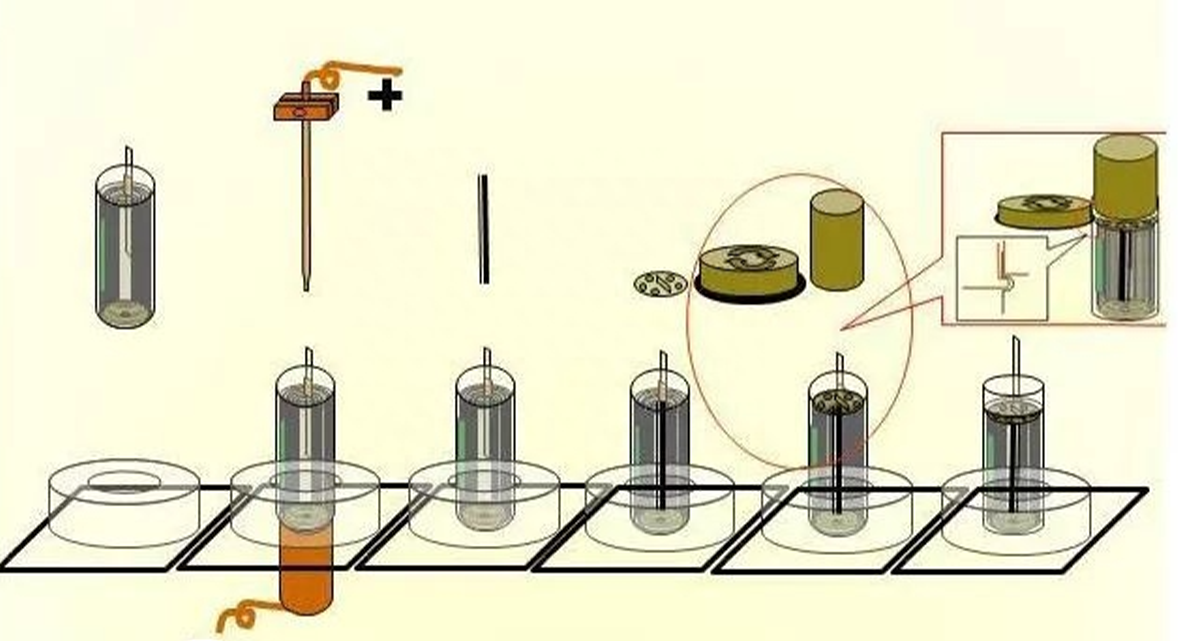

Ukushisela phakathi kwezigxobo zamabhethri e-lithium naphakathi kwezigxobo kanye nomqhubi we-electrolyte kungenye yezinqubo ezibalulekile ekukhiqizeni ibhethri ye-lithium. Isimiso sawo esiyinhloko ukusebenzisa i-high-frequency pulse arc ukuze kufakwe izinga lokushisa eliphezulu kanye ne-high-voltage yamanje phakathi kwesigxobo kanye nomqhubi we-electrolyte, ukuze i-electrode kanye nokuhola kuncibilike ngokushesha futhi kwakhiwe uxhumano oluqinile. Ngesikhathi senqubo yokushisela, imingcele ye-welding efana nokushisa kwe-welding, isikhathi, ingcindezi, njll. idinga ukulawulwa ngokuqinile ukuze kuqinisekiswe izinga lokushisela.

Spot weldingkuyindlela yendabuko yokushisela futhi okwamanje iyindlela yokushisela esetshenziswa kakhulu. Ukusebenzisa isimiso sokushisa kokumelana, izinto zokushisela ziyashisa futhi zincibilike ngokusebenzisana kwamanje nokumelana, kwakha uxhumano oluqinile. I-Spot welding ilungele ukwakhiwa kwezingxenye ezinkulu zebhethri, njengamabhethri emoto kagesi, amabhethri okugcina amandla, njll.

Ukubhaka amaseli ebhethri

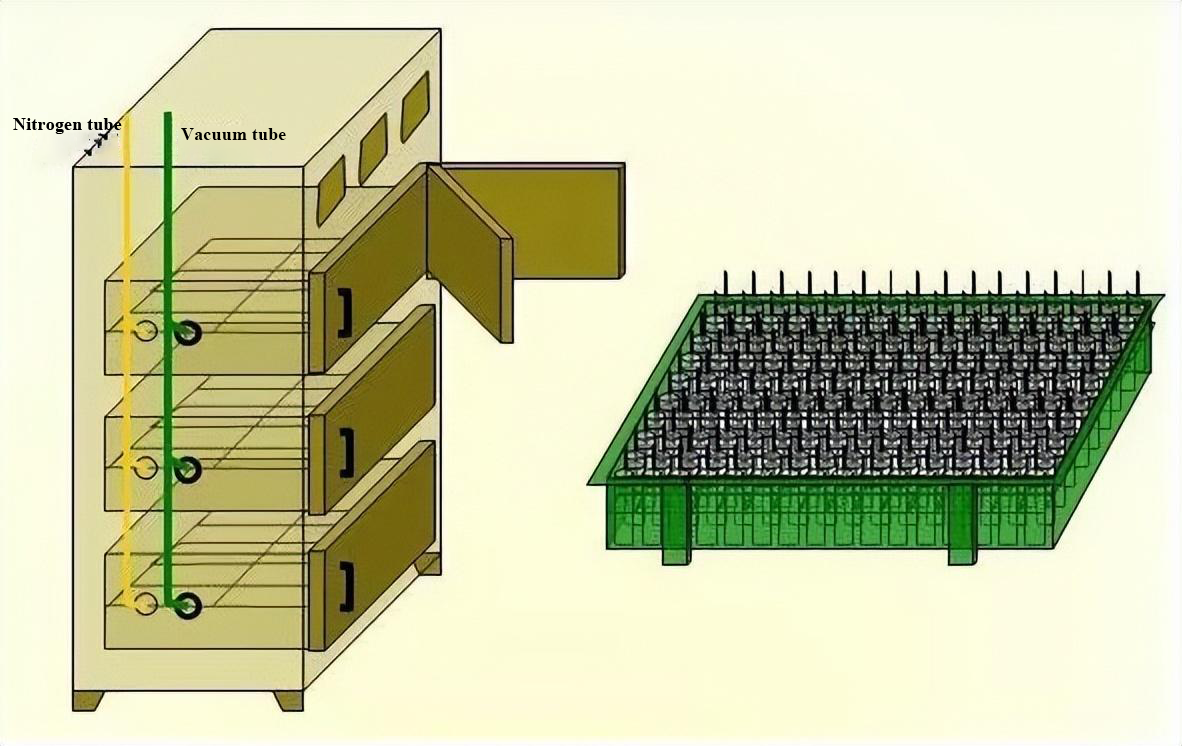

Ukubhaka kudlala indima ebalulekile ekukhiqizeniibhethri ye-lithiumamaseli. Okuqukethwe kwamanzi ngemva kokubhaka kuthinta ngokuqondile ukusebenza kukagesi. Inqubo yokubhaka ingemuva komhlangano ophakathi nangaphambi komjovo we-liquid kanye nokupakishwa.

Inqubo yokubhaka ngokuvamile isebenzisa indlela yokubhaka i-vacuum, impompa imbobo kumfutho ongemuhle, bese ifudumeza izinga elithile lokushisa ukuze kubhake insalela. Umswakama ongaphakathi kwe-electrode usakazekela phezulu entweni ngomehluko wengcindezi noma umehluko wokugxilisa ingqondo. Ama-molecule amanzi athola amandla e-kinetic anele ebusweni bento, futhi ngemva kokunqoba ukukhanga kwe-intermolecular, abalekela ekucindezelekeni okuphansi kwegumbi le-vacuum.

Umjovo

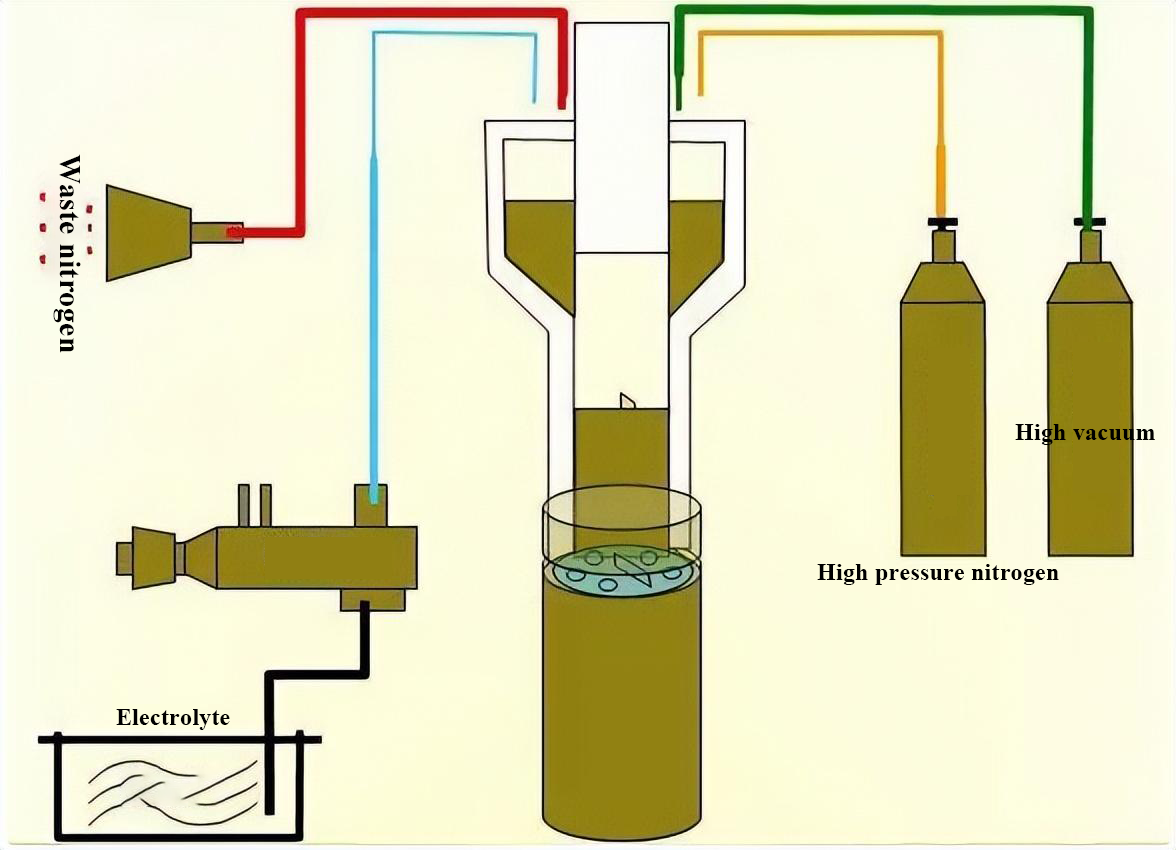

Indima yeibhethri ye-lithiumi-electrolyte iwukwenza ama-ion phakathi kwama-electrode aqondile noma angalungile, futhi asebenze njengendawo yokushaja nokukhipha, njengegazi lomuntu. Indima ye-electrolyte iwukuba iqhube ama-ion, ukuqinisekisa ukuthi ama-ion ahamba ngesilinganiso esithile phakathi kwama-electrode aphozithivu noma anegethivu phakathi nenqubo yokushaja nokukhipha ibhethri, ngaleyo ndlela akhe yonke iluphu yesifunda ukuze ikhiqize amandla amanje.

Umjovo unomthelela omkhulu ekusebenzeni kweseli yebhethri. Uma i-electrolyte ingangenelwanga kahle, izobangela ukusebenza kabi komjikelezo weseli yebhethri, ukusebenza kahle kwezinga eliphansi, kanye nokufakwa kwe-lithium yokushaja. Ngakho-ke, ngemva kokujova, kuyadingeka ukuma ekushiseni okuphezulu ukuze i-electrolyte ingene ngokugcwele ku-electrode.

Inqubo yokukhiqiza umjovo

Umjovo uwukukhipha kuqala ibhethri bese usebenzisa umehluko wengcindezi phakathi kweseli yebhethri nengaphakathi nangaphandle ukuze ushayele i-electrolyte kuseli yebhethri. Umjovo we-Isobaric uwukuqala ukusebenzisa isimiso sokucindezela okuhlukile ukuze ujove uketshezi, bese uhambisa iseli lebhethri elijovwe kusiqukathi esinomfutho ophezulu, bese umpompa umfutho ongemuhle/ukucindezela okulungile kusiqukathi ukuze sijikeleze endaweni emile.

I-Heltec inikeza izinhlobo ezahlukene zokusebenza okuphezuluizindawo zokushiselayakhelwe ngokukhethekile ukushisela insimbi yebhethri. Isebenzisa ubuchwepheshe obuphambili bokushisela, inejubane lokushisela elisheshayo namandla aphezulu we-weld, afanele amabhethri okushisela nemikhiqizo ye-elekthronikhi. Ifakwe uhlelo lokulawula oluhlakaniphile, abasebenzisi bangakwazi ukulungisa kalula amapharamitha wokushisela ukuze baqinisekise ikhwalithi yokushisela engaguquki. Uchungechunge lwethu lwama-spot welder luhlangene futhi lusebenza kalula, lusiza ukuthuthukisa ukusebenza kahle kokukhiqiza nokunciphisa ukusetshenziswa kwamandla. Khetha thina ukuze sikusize uzuze izixazululo ezisebenzayo zokushisela!

Isiphetho

Zonke izinyathelo ku-ibhethri ye-lithiuminqubo yokucubungula idinga ukulawulwa ngokuqinile ukuze kuqinisekiswe ukuphepha nokusebenza komkhiqizo wokugcina. Ngokuthuthuka kobuchwepheshe, izinkampani eziningi nazo zihlala zihlola izinto ezintsha nezinqubo zokuthuthukisa ukuminyana kwamandla kanye nempilo yesevisi yamabhethri.

I-Heltec Energy inguzakwethu omethembayo ekukhiqizeni amaphakethe ebhethri. Ngokugxila kwethu ngokungaphezi ocwaningweni nasekuthuthukisweni, kuhambisana nohlu lwethu olubanzi lwezinsiza zebhethri, sinikeza izixazululo zokuma okukodwa ukuze sihlangabezane nezidingo eziguqukayo zomkhakha. Ukuzibophezela kwethu ekwenzeni okuhle, izixazululo eziklanyelwe, kanye nokusebenzisana okuqinile kwamakhasimende kusenza sibe yinketho kubakhiqizi baphakethe lebhethri nabahlinzeki emhlabeni jikelele.

Uma unemibuzo noma ungathanda ukufunda okwengeziwe, sicela ungangabazifinyelela kithi.

Isicelo sekhotheshini:

U-Jacqueline:jacqueline@heltec-energy.com/ +86 185 8375 6538

Sucre:sucre@heltec-bms.com/ +86 136 8844 2313

U-Nancy:nancy@heltec-energy.com/ +86 184 8223 7713

Isikhathi sokuthumela: Nov-01-2024