Isingeniso:

Amabhethri e-lithiumziwuhlobo lwebhethri elisebenzisa insimbi ye-lithium noma i-lithium alloy njengento engalungile ye-electrode futhi isebenzisa isixazululo se-electrolyte esinganamanzi. Ngenxa yamakhemikhali asebenza kakhulu ensimbi ye-lithium, ukucutshungulwa, ukugcinwa, kanye nokusetshenziswa kwensimbi ye-lithium kunezidingo eziphakeme kakhulu zemvelo. Okulandelayo, ake sibheke izinqubo ze-homogenization, ukunamathela, kanye nokugoqa ekulungiseleleni amabhethri e-lithium.

I-homogenization ye-electrode enhle nebi

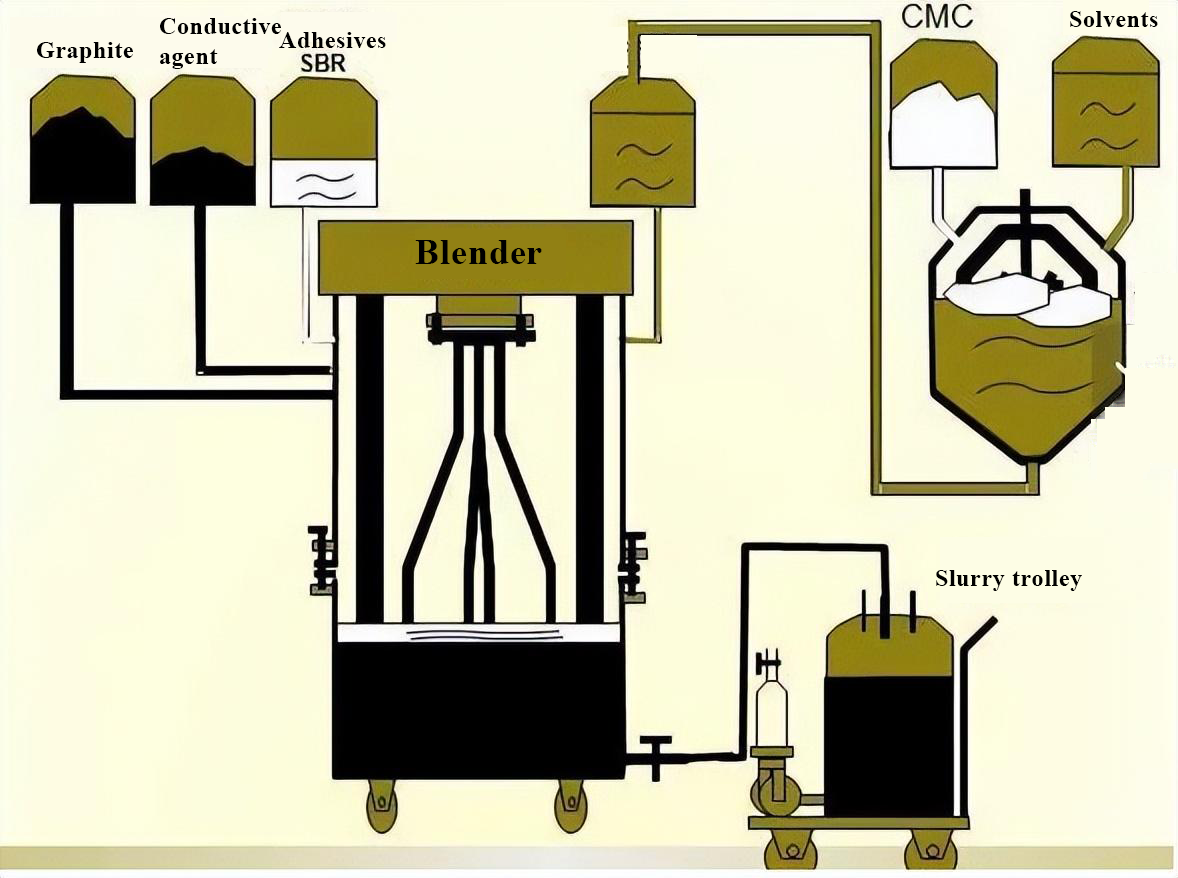

I-electrode yebhethri ye-lithium-ion iyingxenye ebaluleke kakhulu yeseli yebhethri. I-homogenization ye-electrode enhle nebi ibhekisela enqubweni yokulungiselela i-slurry embozwe kumashidi e-electrode e-lithium ion enhle nengalungile. Ukulungiswa kwe-slurry kudinga ukuxuba izinto ezibonakalayo ze-electrode, izinto ezingezinhle ze-electrode, i-agent conductive kanye ne-binder. I-slurry elungiselelwe idinga ukuba ifane futhi izinzile.

Abakhiqizi bebhethri be-lithium abahlukene banamafomu abo enqubo ye-homogenization. Ukuhleleka kokwengeza izinto zokwakha, ingxenye yokwengeza izinto kanye nenqubo eshukumisayo kwinqubo ye-homogenization kunethonya elikhulu kumphumela we-homogenization. Ngemuva kwe-homogenization, i-slurry idinga ukuhlolwa kokuqukethwe okuqinile, i-viscosity, ubuhle, njll. ukuze kuqinisekiswe ukuthi ukusebenza kwe-slurry kuhlangabezana nezidingo.

Ukugqoka

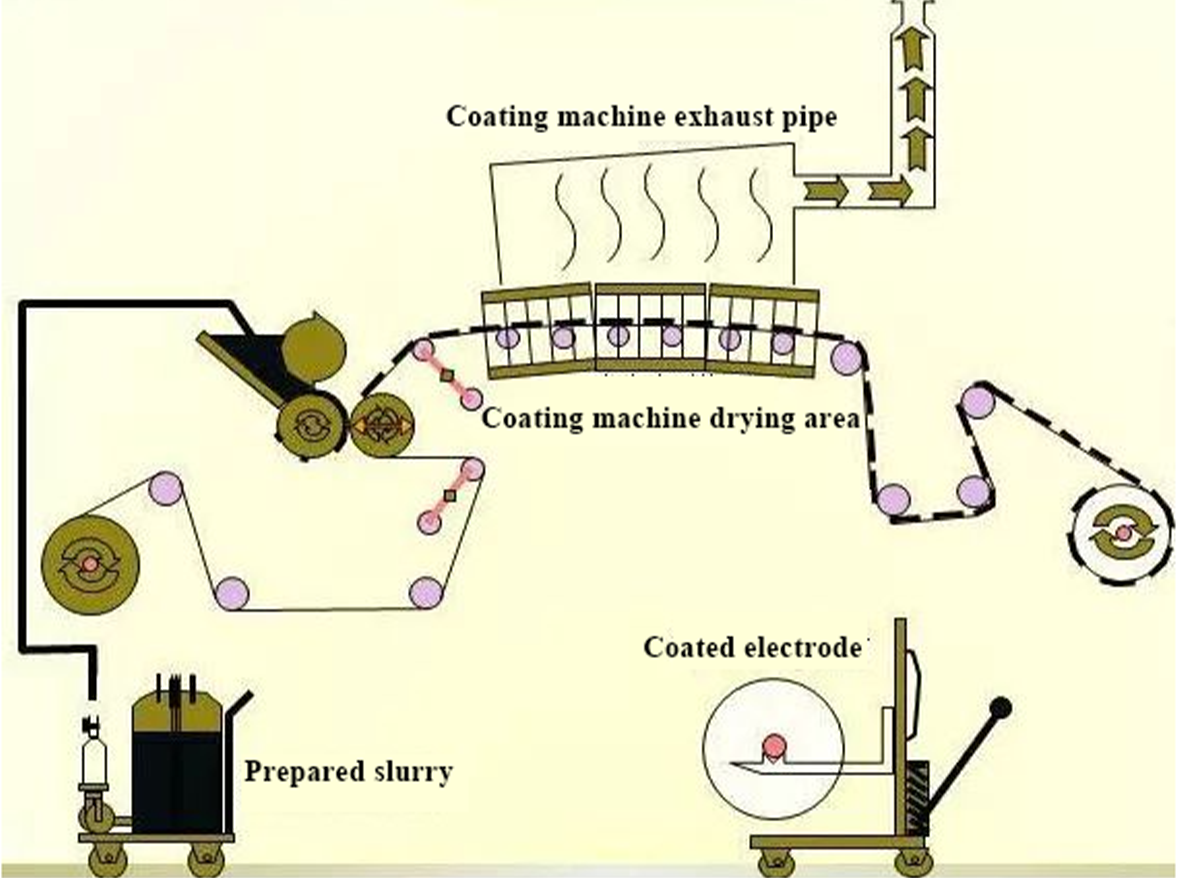

Inqubo yokumboza iyinqubo esekelwe ocwaningweni lwezakhiwo eziwuketshezi, lapho ungqimba olulodwa noma eziningi zoketshezi lumbozwa ku-substrate. I-substrate ngokuvamile ifilimu eguquguqukayo noma iphepha elisekelayo, bese i-coated liquid coating isomile kuhhavini noma iphulukiswe ukuze yenze ungqimba lwefilimu ngemisebenzi ekhethekile.

Ukugqoka kuyinqubo eyinhloko ekulungiseni amaseli ebhethri. Izinga le-coating lihlobene ngqo nekhwalithi yebhethri. Ngesikhathi esifanayo, amabhethri e-lithium-ion azwela kakhulu kumswakama ngenxa yezimpawu zesistimu. Inani elincane lomswakama lingaba nomthelela omubi ekusebenzeni kukagesi kwebhethri; izinga lokusebenza kokumboza lihlobene ngokuqondile nezinkomba ezisebenzayo ezifana nezindleko kanye nesilinganiso esifanelekayo.

Inqubo yokukhiqiza enamathela

I-substrate eboshiwe ikhishwe emshinini wokuvula futhi ifakwe emshinini wokumboza. Ngemva kokuba ikhanda nomsila we-substrate kuxhunywe ukwenza ibhande eliqhubekayo etafuleni lokuhlanganisa, kufakwa kudivayisi yokulungisa ukungezwani kanye nedivayisi yokulungisa ukuchezuka okuzenzakalelayo ngedivayisi edonsayo, bese kufakwa idivayisi yokumboza ngemva kokulungisa ukushuba kwendlela yeshidi kanye nesimo sendlela yeshidi. I-pole piece slurry iboshwe ngezigaba zensimbi yokuhlanganisa ngokuvumelana nenani elinqunywe kusengaphambili kanye nobude obungenalutho.

Lapho i-coating enezinhlangothi ezimbili, i-coating yangaphambili nobude obungenalutho kulandelwa ngokuzenzakalelayo ukuze kuhlanganiswe. I-electrode emanzi ngemva kokumboza ithunyelwa esiteshini sokumisa ukuze some. Izinga lokushisa lokumisa libekwe ngokuya ngejubane lokumboza kanye nokushuba kokumboza. I-electrode eyomile igoqwa ngemva kokulungiswa kwengcindezi nokulungiswa kokuchezuka okuzenzakalelayo kwesinyathelo esilandelayo sokucubungula.

Ukuginqika

Inqubo yokugoqa izingcezu zesigxobo sebhethri ye-lithium iyinqubo yokukhiqiza ecindezela ngokulinganayo izinto ezingavuthiwe njengezinto ezisebenzayo, ama-conductive agents kanye nama-binder ku-foil yensimbi. Ngenqubo yokugingqika, ucezu lwesigxobo lungaba nendawo esebenzayo ye-electrochemical ephakeme, ngaleyo ndlela kuthuthukiswe ukuminyana kwamandla kanye nokushaja nokukhipha ukusebenza kwebhethri. Ngesikhathi esifanayo, inqubo yokugoqa ingenza futhi ucezu lwesigxobo lube namandla aphezulu esakhiwo nokuvumelana okuhle, okusiza ukuthuthukisa impilo yomjikelezo nokuphepha kwebhethri.

Inqubo yokukhiqiza eginqikayo

Inqubo yokugoqa izingcezu zesigxobo sebhethri ye-lithium ikakhulukazi ihlanganisa ukulungiswa kwempahla eluhlaza, ukuxuba, ukuhlanganisa, ukubunjwa nezinye izixhumanisi.

Ukulungiswa kwempahla eluhlaza iwukuxuba izinto ezingavuthiwe ezihlukahlukene ngokulinganayo bese wengeza inani elifanele le-solvent ukuze ugqugquzele ukuze uthole udaka oluzinzile.

Isixhumanisi sokuxuba siwukuxuba izinto ezingavuthiwe ezihlukahlukene ngokulinganayo ukuze kuhlanganiswe nokubunjwa okulandelayo.

Isixhumanisi sokuhlanganisa siwukucindezela i-slurry ngokusebenzisa i-roller press ukuze izinhlayiya zezinto ezisebenzayo zihlanganiswe eduze ukuze zakhe ucezu lwesigxobo esinamandla athile esakhiwo. Isixhumanisi sokubumba siwukuphatha ucezu lwesigxobo ngokushisa okuphezulu nokucindezela okuphezulu ngokusebenzisa imishini efana nomshini wokushisa oshisayo ukulungisa ukuma nobukhulu besiqephu sesigxobo.

.png)

Isiphetho

Inqubo yokulungiselela amabhethri e-lithium iyinkimbinkimbi kakhulu, futhi isinyathelo ngasinye sibalulekile. Hlala ubheka ibhulogi ye-Heltec futhi sizoqhubeka nokukwazisa ngolwazi olufanele mayelana namabhethri e-lithium.

I-Heltec Energy inguzakwethu omethembayo ekukhiqizeni amaphakethe ebhethri. Ngokugxila kwethu ngokungaphezi ocwaningweni nasekuthuthukisweni, kuhambisana nohlu lwethu olubanzi lwezinsiza zebhethri, sinikeza izixazululo zokuma okukodwa ukuze sihlangabezane nezidingo eziguqukayo zomkhakha. Ukuzibophezela kwethu ekwenzeni okuhle, izixazululo eziklanyelwe, kanye nokusebenzisana okuqinile kwamakhasimende kusenza sibe yinketho kubakhiqizi baphakethe lebhethri nabahlinzeki emhlabeni jikelele.

Uma unemibuzo noma ungathanda ukufunda okwengeziwe, sicela ungangabazifinyelela kithi.

Isicelo sekhotheshini:

U-Jacqueline:jacqueline@heltec-energy.com/ +86 185 8375 6538

Sucre:sucre@heltec-bms.com/ +86 136 8844 2313

U-Nancy:nancy@heltec-energy.com/ +86 184 8223 7713

Isikhathi sokuthumela: Oct-23-2024