Umshini Wokushisela Indawo Yesitoreji Samandla

Umshini wokushisela indawo yokugcina amandla uyidivayisi esebenzisa ama-capacitor okugcina amandla ukukhipha ukushisa futhi uzuze ukuxhumana kwe-spot welding yezingxenye zensimbi. Isetshenziswa kakhulu emikhakheni efana nokukhiqiza amabhethri, izingxenye ze-elekthronikhi, nezingxenye zezimoto.

| Ubukhulu bokuqhathanisa | I-Energy Storage Spot Welder | Traditional AC/DC Spot Welder |

| Umthombo Wamandla | Ukukhishwa kwe-capacitor yokugcina amandla (uhlobo lwe-pulse): Igcina amandla ukusuka kugridi ibe ama-capacitor ngokushaja kancane futhi ikhiphe amandla adonswayo khona manjalo ngesikhathi sokushisela. | Ukunikezwa kwamandla egridi eqondile (uhlobo oluqhubekayo): Idonsa amandla kugridi ngokuqhubekayo phakathi nokushisela, incike ku-voltage yegridi ezinzile. |

| Isikhathi sokushisela | I-Milisecond-leveli (1–100 ms): Iqedela ukushisela ngesikhathi esifushane kakhulu ngokufaka ukushisa okuphansi kakhulu. | Amakhulu ama-millisecond ukuya kumasekhondi: Inqubo yokushisela ihamba kancane ngokunqwabelana kokushisa okusobala. |

| Indawo Ethinteke Ukushisa (HAZ) | Okuncane: Amandla agxilile nesikhathi sesenzo esifushane kubangela ukushisela okuncane nokuguga okuncane kokushisa, okulungele izingxenye ezinembayo. | Okukhudlwana: Ukushisisa okuqhubekayo kungase kubangele izinga lokushisa eliphezulu lasendaweni ezintweni zokusebenza, okungase kuholele ekushintshashintsheni noma ekudonseni amanzi. |

| I-Grid Impact | Phansi: Isimanje esizinzile ngesikhathi sokushaja (isb., ukushaja okunezigaba), kanye ne-pulsed current yesikhathi esifushane ngesikhathi sokushisela kubangela ukuguquguquka okuncane kwegridi. | Phezulu: Umthamo ophezulu osheshayo (ofika ezinkulungwaneni ezingamashumi ama-ampere) ngesikhathi sokushisela kungase kubangele ukwehla kungazelelwe kugesi wegridi, okudinga isistimu yokusabalalisa amandla ozinikele. |

| Izimo zohlelo lokusebenza | Izingxenye ezinezindonga ezacile (isb., amafoil ensimbi angu-0.1–2 mm, umkhondo wengxenye ye-elekthronikhi), izidingo zokunemba okuphezulu (isb., ukushisela ithebhu yebhethri ye-lithium), imigqa yokukhiqiza ezenzakalelayo (ehambisana namarobhothi okushisela anesivinini esikhulu). | Ukushisela kwepuleti eliwugqinsi (isb., amapuleti ensimbi angaphezu kuka-3 mm), izimo zokukhiqiza ezingaqhubeki (isb, ukugcinwa, ukucubungula kweqoqo elincane), kanye nezikhathi ezinezidingo eziphansi zejubane lokushisela. |

I-Heltec Uhla Olugcwele Lwe-Spot Welder

Ibhethri Spot Welder 01 Series

Ibhethri Spot Welder 02/03 Series

Umshini Welding Laser

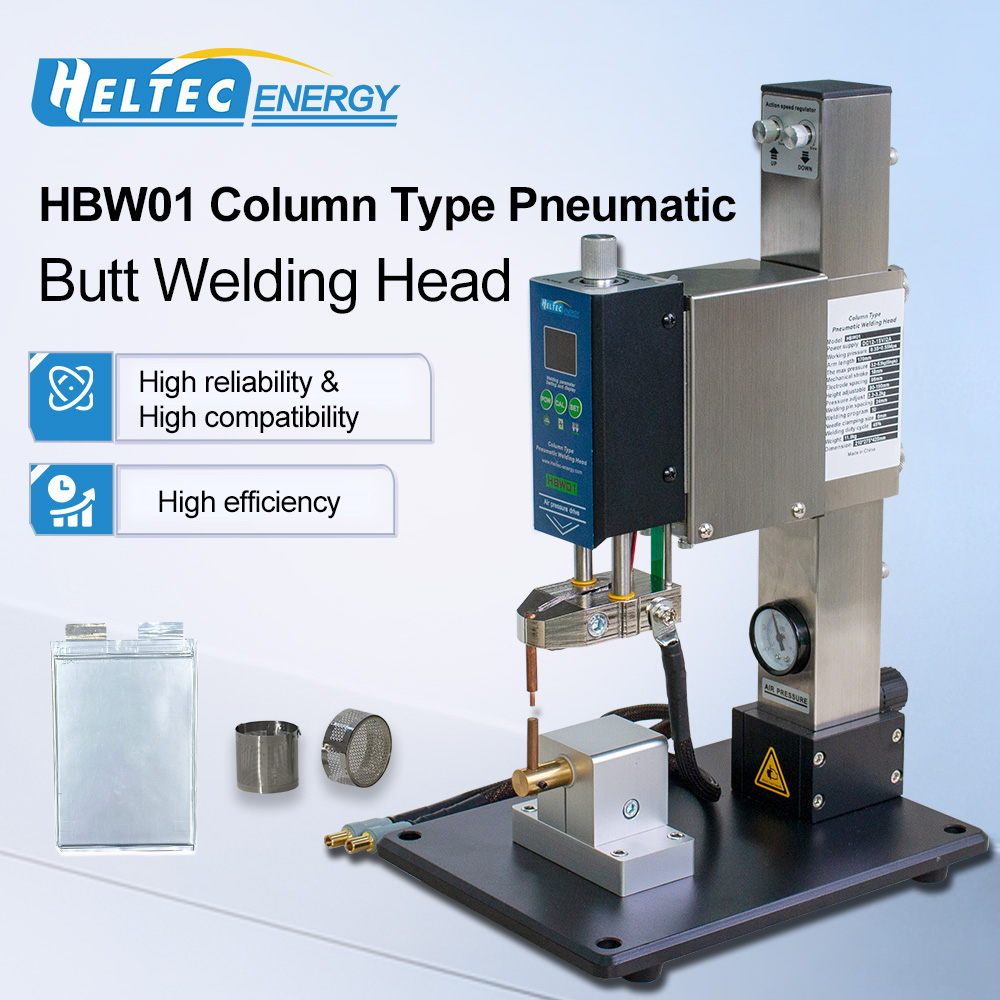

Spot Welder Izesekeli - Spot Welding Head

Inhloko ye-Pneumatic Flat Welding

Inhloko Yokushisela Izinqe Zomoya

Izinzuzo zobuchwepheshe

Ukonga amandla nokusebenza kahle:Ukusetshenziswa kwamandla osheshayo okuphansi kusuka kugridi yamandla, isici samandla aphezulu, umthelela omncane kugridi yamandla, nokonga amandla.

Ikhwalithi enhle yokushisela:Amaphuzu okushisela aqinile, ngaphandle kokushintsha umbala, ukonga inqubo yokupholisha nokusebenza kahle okuphezulu; I-voltage ephumayo izinzile futhi inokuvumelana okuhle, okungaqinisekisa ukuhambisana komphumela womkhiqizo we-welding.

Impilo ende yama-electrode:Uma kuqhathaniswa nemishini yokushisela indawo yendabuko, impilo ye-electrode inganwetshwa ngokuphindwe kabili, kunciphisa izindleko zokusebenzisa.

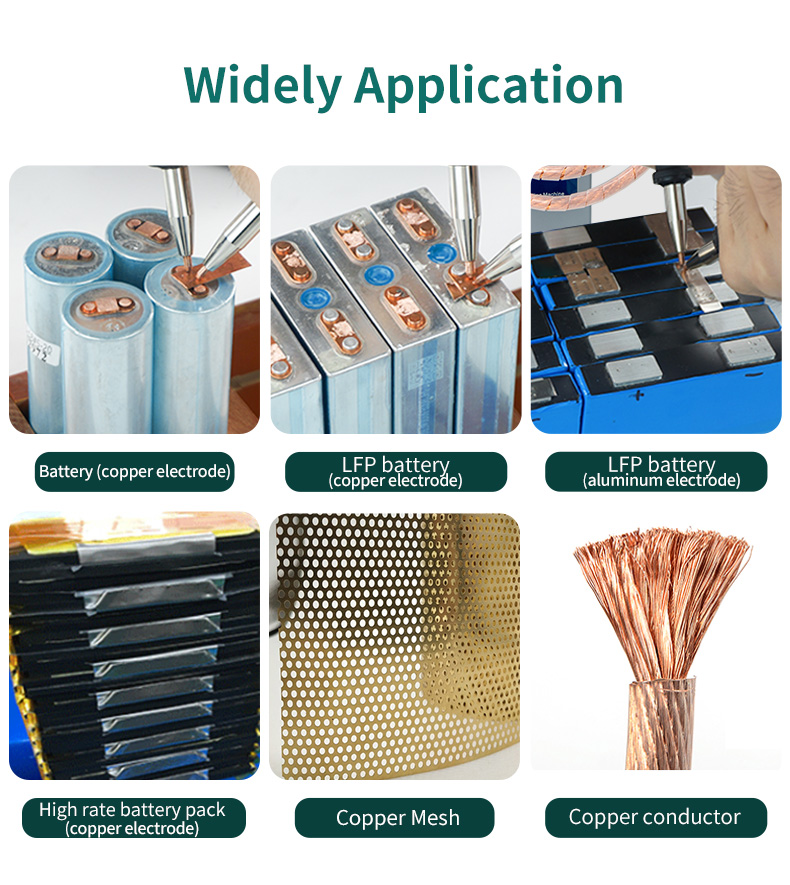

Ukuzivumelanisa nezimo okuqinile:Isebenza kakhulu ezintweni zokushisela, ezifanele izinsimbi ezingezona ayoni kanye nezinto zengxubevange njengethusi, i-aluminium, insimbi engagqwali, nickel, njll; Ikwazi ukuzivumelanisa nezimo ezinhle ekusebenzeni izingcezu ezinogqinsi nobujamo obuhlukene.

Ithebula Lokukhetha Imodeli

| I-SKU | I-HT-SW01A | I-HT-SW01A+ | I-HT-SW01B | I-HT-SW01D | I-HT-SW01H | I-HT-SW02A | I-HT-SW02H | I-HT-SW03A | I-HT-SW33A | I-HT-SW33A+ |

| Isimiso | Isitoreji samandla e-DC | Isitoreji samandla e-DC | Isitoreji samandla e-DC | Isitoreji samandla e-DC | Isitoreji samandla e-DC | Isitoreji samandla e-DC | Isitoreji samandla e-DC | I-AC transformer | Isitoreji samandla e-DC | Isitoreji samandla e-DC |

| Amandla Okukhiphayo | 10.6KW | 11.6KW | 11.6KW | 14.5KW | 21KW | 36KW | 42KW | 6KW | 27KW | 42KW |

| Okukhiphayo Kwamanje | 2000A (Ubukhulu) | 2000A (Ubukhulu) | 2000A (Ubukhulu) | 2500A (Ubukhulu) | 3500A (Ubukhulu) | 6000A (Ubukhulu) | 7000A (Ubukhulu) | 1200A (Ubukhulu) | 4500A (Ubukhulu) | 7000A (Ubukhulu) |

| Amathuluzi Welding Ajwayelekile | 1.70A(16mm²) ipeni lokushisela elihlukanisayo; | 1.70B(16mm²) ipeni lokushisela elihlanganisiwe; | 1.70B(16mm²) ipeni lokushisela elihlanganisiwe; | 1.73B(16mm²) ipeni lokushisela elihlanganisiwe; | 1.75 (25mm²) ipeni le-welding elihlukanisiwe; | 75A(35mm²) ipeni le-welding elihlukanisiwe | 1. Ipeni lokushisela elingu-75A(50mm²). | 1.73B(16 mm²)ipeni le-welding elihlanganisiwe; | Idivayisi ye-A30 yokushisela indawo yomoya. | Idivayisi ye-A30 yokushisela indawo yomoya. |

| I-nickel welding ehlanzekile | 0.1 ~ 0.15mm | 0.1 ~ 0.15mm | 0.1 ~ 0.2mm | 0.1 ~ 0.3mm | 0.1 ~ 0.4mm | 0.1 ~ 0.5mm | 0.1 ~ 0.5mm | 0.1 ~ 0.2mm | 0.15 ~ 0.35mm | 0.15 ~ 0.35mm |

| I-Nickel Plating Welding | 0.1 ~ 0.2mm | 0.1 ~ 0.25mm | 0.1 ~ 0.3mm | 0.15 ~ 0.4mm | 0.15 ~ 0.5mm | 0.1 ~ 0.6mm | 0.1 ~ 0.6mm | 0.1 ~ 0.3mm | 0.15 ~ 0.45mm | 0.15 ~ 0.45mm |

| I-nickel welding ehlanzekile | / | / | / | / | / | 0.1 ~ 0.2mm | 0.1 ~ 0.3mm | / | 0.1 ~ 0.2mm | 0.1 ~ 0.2mm |

| I-Nickel aluminium composite sheet welding | / | / | / | / | 0.1 ~ 0.15mm | 0.1 ~ 0.2mm | 0.15-0.4mm | / | 0.1 ~ 0.3mm | 0.1 ~ 0.3mm |

| I-Copper welding LFP Copper electrode (ene-flux) | / | / | / | / | / | 0.1 ~ 0.3mm | 0.15 ~ 0.4mm | / | 0.1 ~ 0.3mm | 0.1 ~ 0.3mm |

| Ukunikezwa kwamandla kagesi | I-AC 110~220V | I-AC 110~220V | I-AC 110~220V | I-AC 110~220V | I-AC 110~220V | I-AC 110 noma i-220V | I-AC 110 noma i-220V | I-AC 110 noma i-220V | I-AC 110 noma i-220V | I-AC 110 noma i-220V |

| I-Voltage ephumayo | I-DC 5.3V(Ubukhulu) | I-DC 6.0V(Ubukhulu) | I-DC 6.0V(Ubukhulu) | I-DC 6.0V(Ubukhulu) | I-DC 6.0V(Ubukhulu) | I-DC 6.0V(Ubukhulu) | I-DC 6.0V(Ubukhulu) | I-DC 6.0V(Ubukhulu) | I-DC 6.0V(Ubukhulu) | I-DC 6.0V(Ubukhulu) |

| Ukushaja Kwesitoreji Samandla Kwamanje | 2.8A(Ubukhulu) | 2.8A(Ubukhulu) | 4.5A(Ubukhulu) | 4.5A(Ubukhulu) | 6A(Ubukhulu) | 15A(Ubukhulu) | 15A(Ubukhulu) | Akukho ukushaja okudingekayo | 15A -20A | 15A -20A |

| Isikhathi Sokuqala Sokushaja | 30 ~ 40 imiz | 30 ~ 40 imiz | 30 ~ 40 imiz | 30 ~ 40 imiz | Cishe imizuzu engu-18 | Cishe imizuzu engu-18 | Cishe imizuzu engu-18 | Akukho ukushaja okudingekayo, xhuma ukuze usebenzise | Cishe imizuzu engu-18 | Cishe imizuzu engu-18 |

| Imodi yokuqalisa | AT: I-automatic induction trigger | AT: I-automatic induction trigger | AT: I-automatic induction trigger | AT: I-automatic induction trigger | AT: I-automatic induction trigger | AT: I-automatic induction trigger | AT: I-automatic induction trigger | MT: I-foot pedal trigger | MT: I-foot pedal trigger | MT: I-foot pedal trigger |

| Umsebenzi Wokukala Ukuphikiswa Kweshidi Le-Nickel | × | × | × | × | × | × | √ | × | × | × |

| Voltage Test Umsebenzi | × | √ | × | × | × | × | × | × | × | × |

Indawo Yesicelo Somshini Wokushisela Ibhethri Spot

- Spot welding of Lithium iron phosphate battery, Ternary lithium battery,nickel steel.

- Hlanganisa noma lungisa amaphakethe ebhethri nemithombo ephathekayo.

- Ukukhiqizwa kwamaphakethe amabhethri amancane emishini kagesi ephathwayo

- Ukushiselwa kwebhethri ye-lithium polymer, ibhethri likamakhalekhukhwini, kanye nebhodi lesifunda elivikelayo.

- Spot abaholi be-welding kumaphrojekthi ensimbi ahlukene, njengensimbi, insimbi engagqwali, ithusi, i-nickel, i-molybdenum ne-titanium.

Xhumana nathi

Uma unezinhloso zokuthenga noma izidingo zokubambisana zemikhiqizo yethu, sicela ukhululeke ukuxhumana nathi nganoma yisiphi isikhathi. Ithimba lethu lochwepheshe lizozinikela ekukukhonzeni, liphendule imibuzo yakho, futhi likunikeze izisombululo ezisezingeni eliphezulu.

Jacqueline: jacqueline@heltec-energy.com / +86 185 8375 6538

Nancy: nancy@heltec-energy.com / +86 184 8223 7713